Important Facts you need to know about Veneers

Important Facts you need to know about Veneers

What is Veneer plywood?

Veneer, typically made from thin wood layers, serves as a covering for surfaces, often ones that are less attractive or cost-effective. It finds widespread use in crafting furniture, interior design, and construction to enhance the visual appeal of various elements. To create veneer, a thin sheet of wood is obtained by either slicing or peeling it from a log, and then it’s affixed onto a base material like plywood or MDF (medium-density fiberboard). The veneer in plywood enables the development of surfaces that are both visually pleasing and long-lasting, showcasing the natural allure of wood grains while also promoting the conservation of valuable timber resources. Additionally, veneer can be fashioned from alternative materials like stone or plastic, serving diverse decorative and functional purposes. Aauric Elite is one of the best veneer brands in India that produces various types of veneer plywood designs for furniture. They work towards building a luxury living room furniture to help customers live in their dream house.

Facts you need to know about Veneers

The Origin of Veneer

Veneer has a long and diverse history, spanning thousands of years and civilizations. Its origins can be traced back to ancient Egypt, where craftsmen used thin layers of precious woods to enhance furniture and architectural elements. The Romans further refined veneering techniques, incorporating exotic materials like ivory and tortoiseshell in addition to wood.

In the Middle Ages, veneering somewhat declined in Europe, giving way to heavier solid wood construction. However, the Renaissance rekindled interest in veneer, particularly in Italy, where artisans created intricate marquetry designs by skillfully assembling different wood veneer in plywood.

The 18th century saw a resurgence of veneer, with notable furniture makers like Thomas Chippendale and Thomas Sheraton popularizing its use in high-quality pieces. The Industrial Revolution in the 19th century brought about significant advancements, making veneer more accessible through steam-powered cutting machines.

In the 20th century, veneering techniques continued to evolve, incorporating new materials like plastic veneer and synthetic adhesives. This made veneer a common choice in mass-produced furniture, cabinetry, and architectural applications.

Today, veneer remains a versatile choice in modern design and construction, not limited to wood but encompassing materials like stone, metal, fabric, and vinyl. Advances in technology and adhesives ensure the creation of high-quality veneer products with precision and durability, carrying forward the rich history of this craftsmanship to produce luxury living room furniture. Currently Aauric Elite is considered as one of the best veneer brands in India.

The Making of Veneer

Veneer production is a meticulous process used to create thin, decorative sheets of material, typically wood but also various alternatives like stone or plastic. This process involves several key steps. Most of the best veneer brands in India follow a meticulous step to provide the best veneer plywood design.

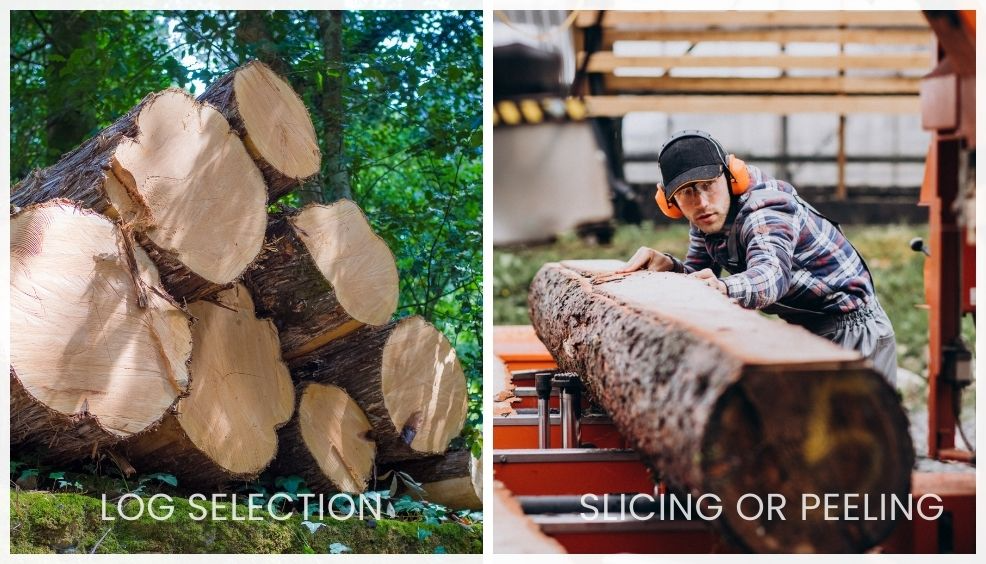

Log Selection and Preparation: High-quality logs with desirable wood grains are chosen and prepared, often by debarking and steaming, to make them suitable for veneer production. At Aauric Elite we always select the best wood to produce veneer in plywood and thus we stay as one of the best veneer brands in India.

Slicing or Peeling: Logs are processed through slicing or peeling methods to create thin sheets of veneer. Slicing involves using a sharp blade to cut veneer sheets from the log’s surface, while peeling entails rotating the log against a stationary knife, producing wider veneer with unique grain patterns.

Drying: Freshly cut veneer sheets contain significant moisture and must be carefully dried to the appropriate moisture content to prevent deformation.

Sorting and Grading: Veneer sheets are inspected and graded based on quality, appearance, and grain patterns, with the finest sheets reserved for premium applications. Most of the best veneer brands in India give importance to providing a high grade product for luxury living room furniture.

Adhesion: Veneer sheets are bonded to a substrate, such as plywood or MDF, using specialized adhesives for a secure and durable bond.

Pressing: The veneer-substrate combination is subjected to pressure and heat in a hydraulic press, ensuring a strong bond between the veneer and the substrate.

Trimming and Finishing: After pressing, panels are trimmed to the desired size and shape, and edges can be finished with veneer edge banding or other treatments.

Sanding and Finishing: Veneered surfaces are sanded to achieve a smooth texture, and finishes like stains or protective coatings may be applied for enhanced appearance, durability and veneer plywood design.

Veneer, with its aesthetic appeal and efficient use of resources, serves diverse applications in luxury living room furniture, cabinetry, interior design, and architectural projects, making it a valuable material with a rich history and a complex, well-honed production process.

Types of Veneer provided by best veneer brands in India

Veneer comes in various types, each offering distinct aesthetics, characteristics, and applications. All the different best veneer brands in India have their own unique style of veneer in plywood. Here are some common types of veneer:

Wood Veneer: Wood veneer is the most traditional and widely used type. It is made from thinly sliced or peeled sheets of natural wood, preserving the unique grain patterns and colors of various wood species like oak, walnut, cherry, maple, and mahogany. Wood veneer is popular in furniture making and interior design for its warm and natural appearance. All the best veneer brands in India use wood veneer.

Reconstituted-Veneer: Reconstituted veneer is engineered from fast-growing or less expensive wood species. Veneer sheets are dyed and arranged to mimic the appearance of rare or exotic woods, making it a more sustainable and cost-effective alternative for achieving specific aesthetics. They are used for wardrobe, wallcovering, desks and bookshelves.

Burl Veneer: Burl veneer is derived from the irregular growths on tree trunks known as burls. These best veneer brands in India display intricate and unique patterns, making them highly sought after for decorative applications. Walnut burl and maple burl are common examples. These are mainly used for luxury living room furniture, home decor and even musical instruments.

Stone Veneer: Thin slices of natural stone, such as slate, granite, or marble, are used to create stone veneer. It replicates the appearance of solid stone and is commonly applied to interior and exterior surfaces for a rustic or elegant look.

Metal Veneer: Metal veneers, like brass, copper, and aluminum, are used for decorative accents or architectural elements. They provide a metallic finish, adding a sleek and modern touch to furniture, walls, or other surfaces.

Plastic Veneer: Plastic veneer can mimic the appearance of wood or other materials and is often used in budget-friendly or high-moisture environments where traditional wood veneer may not be suitable. Most of the veneer in plywood that is found in high moisture climates uses plastic veneer.

These common types of veneer offer a wide range of design options and can be used in various applications, from enhancing the aesthetics of luxury living room furniture and wardrobe to creating distinctive interior and exterior finishes. The choice of veneer type depends on factors like desired aesthetics, budget, and the intended use of the material and it is always best to purchase from the best veneer brands in India.

Factors That Affect Veneers

Several factors can impact the quality, appearance, and performance of veneer materials. Understanding these factors is crucial for making informed decisions about veneer selection and its suitability for specific applications. All the best veneer brands in India will help you . find the best option depending on your necessity. Here are seven common factors that affect veneer:

Wood Species: The choice of wood species significantly influences the appearance of veneer. Different species have distinct grain patterns, colors, and characteristics. Some are prized for their unique aesthetics, while others offer enhanced durability or workability. Aauric Elite best veneer brands in India being one of the best veneer brands in India choose only the best wood species to manufacture their best veneer brands in India .

Grain Pattern: Veneer can be cut or peeled to display various grain patterns, such as plain, quarter-sawn, or rift-sawn. Grain patterns impact the visual texture and overall look of the veneer, affecting its suitability for different design styles. The best veneer brands of India always choose the best grain pattern for luxury living room furniture.

Cutting Method: The method used to create veneer sheets, whether it’s slicing or peeling, affects the appearance. Sliced veneer often results in flat and uniform sheets, while peeled veneer may exhibit a more irregular and cathedral-like grain pattern. The best veneer brands of India choose a cutting method depending on their customer needs.

Veneer Thickness: Veneer sheets come in various thicknesses. Thicker veneer offers increased durability and allows for multiple sandings and refinishing. Thinner veneer is more flexible and suitable for curved surfaces but may have limitations regarding sanding.

Adhesive Quality: The adhesive used to bond the veneer to its substrate is critical. High-quality adhesives ensure a strong and durable bond, contributing to the longevity of the veneered product. The choice of adhesive should align with the specific application and environmental conditions. Aauric Elite being one of the best veneer brands in India always choose the best adhesives to ensure they maintain quality everytime best veneer brands in India .

Substrate Material: The type of substrate material (e.g., plywood, MDF, particleboard) used underneath the veneer impacts the overall stability, weight, and durability of the veneered product. The substrate should be selected based on the project’s requirements.

Moisture Content: Proper drying of veneer is essential to prevent warping, buckling, or other defects. The moisture content of the veneer should be appropriate for the intended application and the environment where it will be used. All the best veneer brands in India check for moisture content to maintain quality.

Finishing and Coating: The choice of finish, such as stains, lacquers, varnishes, or protective coatings, can affect the appearance and durability of the veneer. Different finishes may enhance or alter the color and sheen. To get a good finishing and coating for your luxury living room furniture it is always best to use the best veneer brands of India.

Environmental Factors: Environmental conditions, including humidity and temperature, can impact the stability of veneer. It’s essential to acclimate veneer to the environment where it will be installed to minimize potential issues.

Considering these factors when working with veneer materials is crucial for achieving the desired aesthetics, longevity, and performance in various applications, whether it’s in furniture, cabinetry, interior design, or architectural projects and best veneer brands in India.

Auric Elite best veneer brands in India has consistently held its reputation as one of the best veneer brands in India, owing to its enduring commitment to delivering top-notch products. We treat our customers’ preferences and desires as if they were our own, ensuring that we offer the highest quality to assist them in realizing their aspirations..

Author

adminRelated posts

Flourishing interiors with laminates: What Laminate Brands in India Can Offer You

Flourishing interiors with laminates: What Laminate Brands in India Can Offer Yo

How to choose the best plywood for interiors

How to choose the best plywood for interiors Every house has its aesthetics depe

Significant things you need to know about the best plywood for wardrobe

Significant things you need to know about the best plywood for wardrobe Building