What is commercial plywood and what are its uses

What is commercial plywood and what are its uses

You might have heard commercial plywood various times but not sure about what it is. It is also known as moisture-resistant plywood or MR plywood. It is a common building material that is often used in construction and interior design applications. This plywood is crafted from layers of wood veneers that are bonded together using an adhesive like phenol-formaldehyde. This plywood has a unique cross-grain pattern where the direction of the wood grain alternates in adjacent layers. This cross-graining pattern gives strength, stability and resistance to warping.

When you hear the word commercial you might immediately consider it as a lower standard plywood but instead, it simply means general-purpose plywood that is suitable for a variety of commercial and residential projects. As commercial plywoods have more layers of plywood they are preferred more when it comes to building strong cabinets, and durable furniture as they are waterproof plywood.

Advantages of Commercial plywood

Strength and Stability: Commercial plywood is known for its remarkable strength and stability, making it an excellent choice for various applications. One of the main advantages of commercial plywood is its high level of durability, as it is built to withstand the rigours of everyday use. This exceptional strength ensures that plywood can support heavy loads without warping, bending, or breaking, making it suitable for construction projects that require sturdy materials. Additionally, commercial plywood is known for its stability, which means that it does not easily expand or contract due to changes in temperature or humidity. This stability is crucial in maintaining the structural integrity of plywood, ensuring that it retains its shape and dimensions over time. Moreover, the strength and stability of commercial plywood make it easier to work with, allowing for various types of cuts, shapes, and finishes. This versatility opens up a wide range of possibilities for its use in both interior and exterior applications. Whether it is for building furniture, cabinets, flooring, or even concrete formwork, commercial plywood’s strength and stability provide durability and reliability. Overall, the numerous advantages of commercial plywood make it an optimal choice for construction projects, offering long-lasting performance and peace of mind.

Durability: Commercial plywood is prestigious for its extraordinary toughness, making it a favoured decision for a heap of uses in development, furniture, and different ventures. One of the critical benefits of compressed wood lies in its strong arrangement, normally comprising various layers of wood that are fortified along with glue. This layering upgrades the strength of the pressed wood as well as give obstruction against distorting, breaking, and parting, guaranteeing a dependable and stable material.

Plywood is often made utilising great wood species, like hardwoods or softwoods, contingent upon the expected use. This cautious choice of wood adds to the general sturdiness of the compressed wood, as it guarantees that the material can endure fluctuating natural circumstances and outside anxieties. Also, top-quality plywood is treated with adhesives and synthetic compounds during the assembling system, further improving its protection from rot, bugs, and growths.

The sturdiness of waterproof plywood additionally stretches out to its capacity to endure changes in temperature and moistness, making it reasonable for both inside and outside applications. Its layered security guarantees that it keeps up with its shape and underlying trustworthiness after some time, even in testing ecological circumstances. This component is especially worthwhile in development projects where the pressed wood might be presented to the components, guaranteeing a dependable and durable structure material.

Easy to work on: Commercial plywood stands apart as a favoured decision in carpentry and development because of its intrinsic simplicity of functionality. This trademark makes it a lean toward material for woodworkers, developers, and specialists. Plywood, ordinarily including different layers of wood facade reinforced along with glue, is considered easy to cut, mould, and machine. Its predictable and uniform design guarantees that it very well may be handily controlled utilising normal carpentry devices, like saws, switches, and bores. This functionality is especially favourable in making perplexing plans and custom-fitted pieces, as modern plywood obliges different cutting and moulding procedures with accuracy.

Moreover, the smooth and, surprisingly, surface of plywood loans itself well to completing cycles. Whether it’s painting, finishing, or veneering, the pressed wood promptly acknowledges these medicines, bringing about a finished and tastefully satisfying eventual outcome. The straightforwardness with which plywood can be chipped away improves its flexibility as well as smoothes out development processes, diminishing work time and expenses. Basically, the easy-to-use nature of plywood makes it an ideal decision for projects where the simplicity of functionality is fundamental, taking into account the production of top calibre and redid things with productivity and accuracy.

Budget-friendly: One of the conspicuous benefits that separates plywood is the commercial plywood price, making it a go-to decision for many applications. Plywood is produced utilizing financially savvy wood species, like softwoods, without settling for less primary trustworthiness. This reasonable commercial ply rate is a favoured choice for projects where financial plan requirements are a basic thought.

In addition, the adaptability of plywood adds to its expense viability. Its reasonableness for different applications, including furniture and cabinetry guarantees that a solitary material can fill various needs, decreasing the requirement for various materials for various undertakings. Also, the simplicity of usefulness of modern plywood smoothes out establishment processes, further limiting work costs.

Availability: Modern plywood flaunts a huge benefit in its far-reaching accessibility, making it a promptly open and flexible structure material. Its creation is smoothed out to satisfy high needs, guaranteeing a steady stock on the lookout. This openness is especially invaluable for enormous-scope development ventures and large-scale manufacturing of furniture, where a dependable and adequate inventory of materials is fundamental. Business compressed wood is often loaded by a huge number of providers, including neighbourhood home improvement shops, making it helpful for developers, workers for hire, and specialists to effectively source the material.

Moreover, the accessibility of the best plywood comes in different thicknesses and grades, taking special care of assorted project prerequisites. This flexibility makes it a go-to decision for many applications, from straightforward Do-It-Yourself undertakings to complex development tries. The easy availability of plywood is due to the rivalry in the market that frequently brings about a reasonable estimate, helping both individual purchasers and organizations the same.

In summary, the boundless accessibility of plywood guarantees that it stays a go-to decision for those needing a dependable, flexible, and effective possible structure material. This openness adds to the material’s prevalence across various ventures and undertakings, building up its status as a functional and helpful choice for development and carpentry needs.

Waterproof: One of the critical benefits of plywood lies in its waterproof properties, going with it a flexible and sturdy decision for different applications. Water-resistant plywood is frequently treated with water-safe coatings and glues during the assembling system, furnishing it with the capacity to endure openness to dampness, mugginess, and, surprisingly, intermittent sprinkles.

This makes it appropriate for use in conditions where customary compressed wood may be helpless to water harm, like in restrooms, kitchens, or outside structures. The waterproof plywood not only improves its life span by forestalling twisting or delamination yet in addition extends its scope of possible applications, permitting it to perform dependably in conditions where dampness obstruction is critical. Whether utilised in furnishings, development, or marine applications, moisture-resistant plywood adds an important aspect to flexibility and strength.

Uses of Commercial plywood

Commercial plywood, attributable to its adaptable properties, tracks down broad applications across different enterprises. Here is a definite investigation of its different purposes:

Furniture Manufacturing:

Plywood is a staple in the furniture business, used for creating a wide exhibit of things like tables, seats, cupboards, shelves, and closets. Its soundness, strength, and simplicity of usefulness make it a favoured decision for the two producers and skilled workers.

Interior Construction:

In interior construction, plywood is usually utilised for applications like wall framing, bogus roofs, and segments. Its smooth surface is considered simple wrapping up with paints, overlays, or facade, adding to tastefully satisfying insides.

Exterior Construction:

Treated plywood with waterproof properties is reasonable for outside applications. It is utilized in the development of entryways, window screens, and formwork, giving strength and protection from weather patterns.

Flooring:

Packaging:

The strength and solidness of plywood make it an optimal decision for packaging materials. It is often utilised in the development of cases, boxes, and beds, giving solid security to merchandise during transportation.

Boat Building:

Marine-level plywood, intended to oppose water harm, is broadly utilized in boat and yacht development. Its capacity to endure openness to dampness makes it a significant material for marine applications.

Signage and Displays:

Because of its smooth surface and simplicity of making furniture, plywood is utilized in making signage and show structures for organizations. It fills in as a durable and adaptable material for publicizing and limited-time purposes.

DIY Projects:

Property holders and Do-It-Yourself lovers frequently pick commercial plywood for various activities. Its accessibility in various thicknesses and grades makes it appropriate for everything from basic furniture to more complicated carpentry errands.

Industrial Applications:

Plywood is used in different modern applications, including the development of bundling materials, and beds, and the assembling of apparatuses and dances in manufacturing plants.

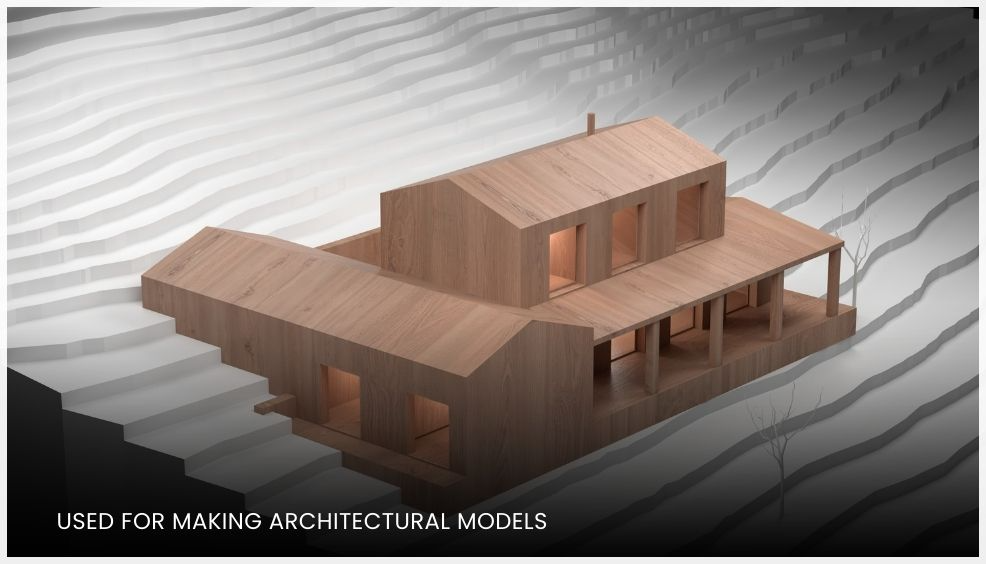

Architectural Models:

Its uniform surface and simplicity of cutting make plywood reasonable for making compositional models. Planners and fashioners frequently use compressed wood to rejuvenate their plan ideas in an unmistakable structure.

In rundown, the flexibility, strength, and accessibility of commercial plywood make it an adaptable material that takes special care of the different necessities of ventures going from development and furniture to packaging and more. Its broad use highlights its significance as a key structure material.

Author

adminRelated posts

Flourishing interiors with laminates: What Laminate Brands in India Can Offer You

Flourishing interiors with laminates: What Laminate Brands in India Can Offer Yo

Significant things you need to know about the best plywood for wardrobe

Significant things you need to know about the best plywood for wardrobe Building

Laminate vs Veneer: What makes a laminate different from a veneer?

Laminate vs Veneer: What makes a laminate different from a veneer? When you were

12 Comments

Comments are closed.

Pingback: rybelsus online sales