Important facts you need to know about Plywood

Important facts you need to know about Plywood

What is Plywood?

Plywood stands as a versatile and extensively employed engineered wood product, forged from numerous slender wood veneer layers conjoined with adhesive. These veneers commonly originate through the peeling or slicing of logs and are strategically positioned to alternate the orientation of wood grain from one layer to the next. This configuration, known as cross-grain construction, imparts to plywood remarkable strength, stability, and a heightened ability to withstand warping and splintering. Most top plywood companies thrive to provide top quality plywood to their customers. Aauric Elite is well known for their top quality plywood for 30 years.

7 facts you need to know about top quality plywood

1. The origin of plywood

Plywood has a rich history dating back thousands of years. Ancient Egyptians and Romans used thin layers of wood glued together for various applications. However, modern plywood as we know it today began to take shape in the 19th century.

The concept of plywood evolved significantly with the invention of steam-powered rotary cutting machines in the mid-1800s. These machines allowed for efficient and consistent slicing of veneer from logs. In the mid-20th century, advances in adhesive technology, specifically the development of synthetic glues like phenol-formaldehyde, greatly improved the strength and durability of plywood.

During World War II, plywood saw increased use due to its versatility and strength. It was employed in various military applications, from constructing aircraft parts to creating lightweight boats. Post-war, top quality plywood gained popularity in construction, furniture-making, and other industries due to its affordability, stability, and ease of use.

Today, top quality plywood continues to be a vital construction material worldwide, with various grades and types catering to diverse applications. It remains a key player in industries ranging from architecture and interior design to packaging and manufacturing.

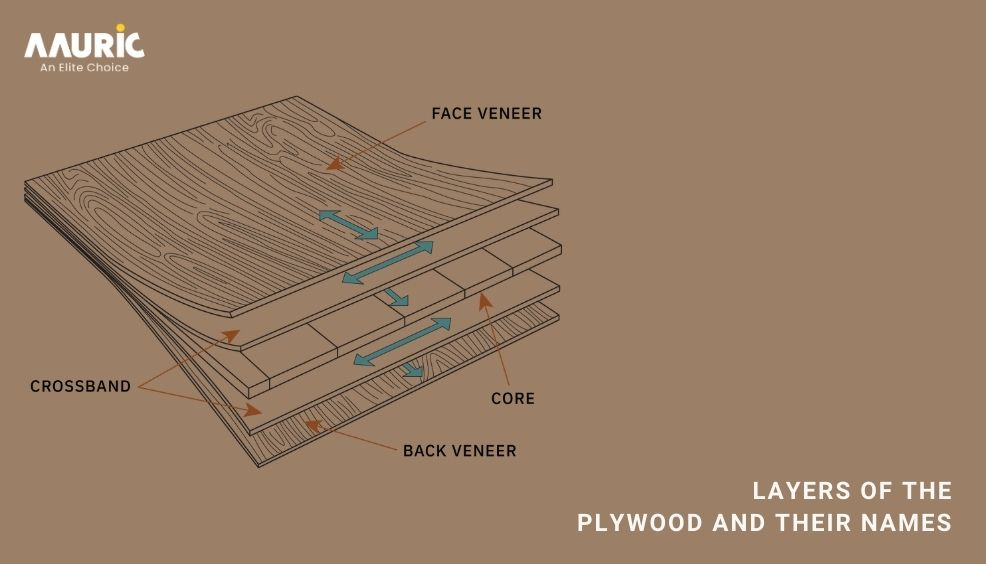

2. Layers of the plywood and their names

Plywood is composed of multiple layers of thin wood veneers that are glued and pressed together to create a strong and versatile sheet material. These layers are known as “plies.” The number of plies and their arrangement contribute to the strength, stability, and properties of the plywood sheet. Here’s a general breakdown of the layers in a typical piece of plywood:

Face/Back Veneer: This is the outermost layer of the plywood sheet that is visible when the sheet is used in a project and this determines a top quality plywood It’s often made from a higher quality wood species and is chosen for its appearance and finish. Premium and thick Gurjan Face/Back veneers are used in Aauric Elite plywoods which is one among the best plywood company

Core Layers: Between the face and back veneers, there are several core layers, sometimes called inner plies or crossbands. These layers are arranged in a way that the grain direction of adjacent layers is perpendicular to each other. This cross-grain arrangement enhances the plywood’s strength, stability, and resistance to warping.

Adhesive: Each layer of veneer is bonded together with adhesive, typically a type of resin or glue. The quality of the adhesive plays a crucial role in determining a top quality plywood, as it’s responsible for holding the layers together and providing cohesive strength. At Aauric Elite we premium quality formaldehyde emission friendly resin in our plywoods and thus we are one among the best plywood company

The number of layers in a plywood sheet can vary based on its intended use and grade, top Plywood commonly adheres to standard dimensions of 4 feet by 8 feet or 4 feet by 7 feet, and it comes in various thicknesses, spanning from 4mm – 25mm.

While the precise construction and composition of plywood can differ among manufacturers and types, the fundamental concept of layering remains consistent.

3. Grades of Plywood

Plywood undergoes categorization into distinct grades based on quality, intended application, and visual attributes. This grading framework aids individuals in selecting plywood that aligns with their specific project needs. Below are prevalent plywood grades:

A Grade: Distinguished by a sleek and uniform appearance, A grade plywood exhibits minimal knots, flaws, and voids on the face veneer. This is considered to be the top quality plywood in the industry. It is a preferred choice for projects emphasizing aesthetics, like furniture and wardrobe. Aauric Elite uses A Grade top quality plywood to provide the best quality plywood furniture.

B Grade: B grade is also a top quality plywood but may display minor imperfections such as small knots, burls, and patches on the face veneer. It suits applications valuing appearance while accommodating minor irregularities.

C Grade: Characterized by more prominent knots, repairs, and variations in color on the face, C grade plywood is often used in structural contexts where visual appeal takes a backseat.

D Grade: D grade plywood features larger knots, visible defects, and patches on the face veneer. It finds utility in applications where the plywood’s structural robustness takes precedence over its visual appearance.

Moisture Resistant (MR) Grade Plywood: Moisture-resistant grade plywood (MR plywood) is designed to withstand moderate moisture exposure. It’s used indoors, like in kitchens and bathrooms, where humidity is a concern. It offers better protection against warping and fungal growth compared to standard plywood but isn’t suitable for continuous wet conditions or outdoor use.

Boiling Water Resistant (BWR) Grade Plywood: BWR plywood, short for boiling water-resistant plywood, is specially made to endure extended exposure to moisture, even boiling water. It utilizes unique adhesive formulations that grant exceptional resistance to water damage. It’s ideal for applications demanding top-tier moisture resistance, like kitchen cabinets and furniture exposed to water. BWR plywood excels in preventing swelling, delamination, and fungal growth in high-moisture settings.

Boiling Water Proof (BWP) Grade Plywood or Marine Grade Plywood: BWP Grade Plywood, often called Marine Grade Plywood, is the top quality plywood choice for extreme moisture and water resistance. It’s made with high quality waterproof adhesives and premium veneers, making it perfect for projects continuously exposed to water, like boat building, docks, and outdoor structures. BWP top quality plywood excels in preventing swelling, delamination, and fungal decay in wet environments.

These are just a few examples of plywood grades, and the specific grading names and criteria can vary between regions and standards organizations. When selecting plywood for a project, it’s important to consider the intended use, aesthetics, and performance requirements to choose the appropriate grade.

4. Types of plywood and their uses

It might come as a surprise to many but there are various types of plywood and each plywood’s unique feature is used based on the specific requirement.

Softwood plywood: Softwood plywood is a type of plywood that is made from layers of softwood veneers bonded together with adhesive. The veneers are typically sourced from coniferous trees such as pine, spruce, cedar, or fir. Softwood plywood is affordable, easily available, and structurally versatile.

Softwood plywood comes in different grades and thicknesses, making it suitable for a range of projects. It’s commonly used for construction and woodworking, sheathing roofs and walls, flooring underlayment, wardrobe, and general woodworking tasks. The specific type and grade of softwood plywood you choose will depend on the requirements of your project, such as load-bearing capacity, exposure to moisture, and aesthetic considerations.

Hardwood plywood: Hardwood plywood is a type of plywood that is made from layers of hardwood veneers bonded together with adhesive. Unlike softwood plywood, which is made from coniferous trees, hardwood plywood is manufactured majorly from eucalyptus plantation trees thus not having any impact on the environment.

Hardwood plywood is valued for its durability, strength, and attractive appearance. It is commonly used in high-quality furniture making, cabinetry and wardrobes, interior paneling, decorative wall coverings, and other applications where a fine finish and sturdy construction are important. The hardwood veneers used in this type of top quality plywood can vary in thickness and quality, allowing for a wide range of options to suit different project requirements. Auric offers a range of top quality plywood options, catering to both budget-conscious customers and those seeking premium quality. This diverse selection ensures that interior spaces can be adorned with a touch of elegance and refinement. Be it budget friendly or premium product Aauric Elite always ensures top quality plywood for their customers.

Aircraft plywood: Aircraft plywood, also known as aviation-grade plywood, is a specialized type of plywood that is engineered to meet the stringent requirements of the aviation industry. It is designed to be extremely lightweight, strong, and durable, making it suitable for use in aircraft construction and other aerospace applications.

Aircraft is the top quality plywood is usually constructed with high-quality hardwood veneers and a specific type of adhesive that ensures superior bonding under varying temperature and pressure conditions. This type of top quality plywood undergoes strict quality control measures to ensure consistent thickness, strength, and integrity.

5. The making of Plywoods

Plywood is created by layering thin wood veneers and bonding them with adhesive. The process includes log preparation, where wood is cut into veneers, followed by drying to reduce moisture. Veneers are sorted based on quality, coated with adhesive, and layered with alternating grain directions. The layers are pressed together using heat and pressure, then trimmed to size. Depending on use, finishing processes like sanding or coatings are applied. The specific manufacturing process can vary based on the type of plywood being produced and the equipment used by the manufacturers. Different types of plywood, such as marine plywood and hardwood plywood, may involve additional steps or variations in the process to meet specific requirements. Auric Elite’s top quality plywood consistently adheres to a meticulously planned quality-oriented process, employing advanced machinery to deliver top quality plywood within the industry.

6. Lifetime of plywood

The lifespan of plywood hinges on a multitude of factors that collectively determine its durability and endurance. Firstly, the quality of the plywood significantly influences how long it will last; those crafted from top-notch materials using advanced manufacturing processes tend to exhibit superior longevity. The usage environment plays a pivotal role, with indoor applications within controlled conditions generally leading to a lengthier lifespan when compared to plywood exposed to harsh outdoor elements, severe weather fluctuations, or high humidity levels. Constant exposure to moisture, whether due to outdoor applications or bathrooms, can render plywood susceptible to delamination and decay, potentially reducing its lifespan. Engaging in routine maintenance practices, such as sealing and painting, emerges as a proactive measure to significantly extend the lifespan of plywood, as it creates a protective barrier against environmental stresses. Certain specialized plywood variants, like marine plywood engineered to be waterproof, are tailor-made for prolonged endurance in wet environments. Lastly, the lifespan of plywood utilized in structural roles might experience a decrease when subjected to consistent heavy loads over time. Hence, a comprehensive consideration of these factors is essential during the selection and application of top quality plywood to ensure optimal performance and durability across various contexts.

7. Factors that affect plywood

The quality of plywood is influenced by several key factors that collectively determine its strength, durability, and overall performance:

- Raw Material Quality: The type and grade of wood used to create the veneers significantly impact plywood quality. Premium woods result in higher-quality plywood.

- Veneer Thickness and Uniformity: Consistent veneer thickness across layers contributes to structural integrity and stability.

- Adhesive Performance: The type and quality of adhesive used for bonding layers together affect resistance to moisture, temperature changes, and delamination.

- Number of Layers: Plywood with more layers generally exhibits greater strength and stability.

- Grain Alignment: Proper alignment of the wood grain in adjacent layers enhances strength and minimizes warping.

- Moisture Content: Properly dried veneers are critical to prevent warping, shrinkage, and potential decay.

- Manufacturing Process: Meticulous manufacturing processes that ensure uniform bonding, consistent thickness, and minimal defects contribute to quality.

- Grade Standards: Plywood is graded based on appearance and structural attributes. Higher-grade plywood usually has fewer defects and better overall quality.

- Surface Smoothness: Smooth, even surfaces without voids or imperfections contribute to both aesthetics and functionality.

- Resistance to Environmental Factors: High-quality plywood is designed to withstand moisture, temperature variations, and other environmental stresses.

- Application-Specific Features: Specialty plywood designed for specific applications, such as marine or aircraft plywood, has unique features that enhance its quality for those uses.

Considering these factors when purchasing plywood ensures that you select the right quality for your intended application, whether it’s for construction, furniture, cabinetry, or other projects.

Aauric Elite’s top quality plywood stands as a reputable brand, committed to delivering top quality plywood. Our unwavering dedication involves the use of premium wood and meticulous oversight throughout the plywood manufacturing process. We are driven by the aspiration to provide superior living environments for all.

Author

adminRelated posts

Flourishing interiors with laminates: What Laminate Brands in India Can Offer You

Flourishing interiors with laminates: What Laminate Brands in India Can Offer Yo

Mastering your kitchen makeover: Key considerations for selecting the best kitchen interior designers in India.

Mastering your kitchen makeover: Key considerations for selecting the best kitch

Important Facts you need to know about Veneers

Important Facts you need to know about Veneers What is Veneer plywood? Veneer, t

Pingback: best veneer plywood